|

|

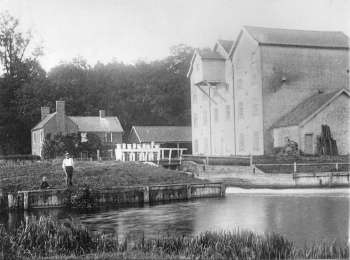

c.1905

|

|

Oxnead Mill

River Bure |

|

|

c.1905

|

|

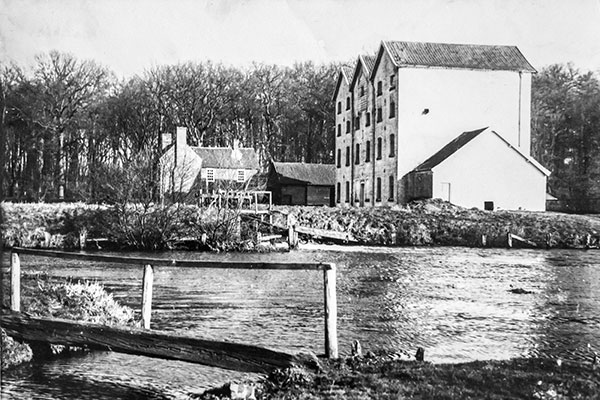

Oxnead Mill

was another Domesday mill. From at least 1716 and up until 1822, Oxnead

was a paper mill. In 1822 it was converted to make blankets before once

again being rebuilt as a flour mill. A stone plaque indicates that this

took place in 1850-1 using white painted brick with a Norfolk pantiled

roof. The design was slightly unusual, consisting of 3 adjoining gabled

sections. Being on the Aylsham Navigation there were two lucums, one on

land and one above the water. In 1940 the mill was once more turned over

to paper production. |

|

|

c.1900 |

|

|

|

Oxnead lock c.1910 before the flood

|

Oxnead

lock in 1912 after the flood |

|

|

Oxnead

lock 7th September 2008 |

|

WATER MILLS

To be LET on lease for a Term of Years, SITUATE AT OXNEAD, NEAR AYLSHAM, In the County of Norfolk, Upon the never-failing River BURE, navigable to Yarmouth, |

| THEY were formerly Paper Mills, and for the last 28 years have been

in the occupation of Robert and Page Bleakley, as Woollen Manufacturers,

whose lease expires at Michaelmas next, and their machinery (if required)

can be taken in the usual way. These Mills are in a fine and highly-cultivated agricultural district, and are well adapted to any trade requiring power and warehouse room, as they cover a large space, and can be hired without any payment for machinery. There is a capital Residence, Stabling, Farming Buildings, and Piggery for upwards of 100 Pigs. About 20 Acres of Land can be had if required. For further particulars, apply to Mr. J. Warnes, Bolwick Hall, near Aylsham; Mr. G. E. Simpson, Solicitor, or Mr. W. Thorold, Engineer, both of Norwich. Norfolk Chronicle - 9th June 1849 |

|

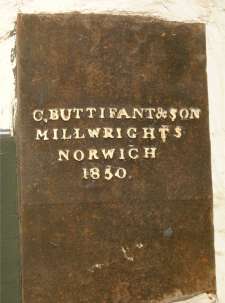

Sir E. Stracey, Bart. Oxneade. I beg to lay before you an Estimate for Machinery for a new Water Mill at Oxneade, viz, New Water Wheel 18ft. 6in. high, 12ft.wide, 4 cast iron rings put together in halves with good strong bolts, cast iron brackets, round rings to carry the floats, well bolted to the rings, memel fir floats and back boards, new breast, two good oak staple posts 10x14in oak, mud cill 10x14, Cap cill 8x10in oak, live breast made of good 4in oak plank well bolted together. 2 cast iron racks, 2 pinions, iron guide rolls, carriages, bolts &c. ham'd, iron laying shaft, worm and worm wheel, carriages & bolts &c. to draw breast with. Cast iron steadfast breast, new backshut, 2 staple posts 8x12. Cap cill 8x12in. mudcill 8x10, oak gate 4in. thick with good oak struts 6x3in. 2 Cast iron racks, 2 pinions, rolls, carriages, laying shaft, worm & worm wheel, bolts &c. Cast iron Water Wheel Shaft, with 3 bearings, 3 cast iron carriages, 3 bell metal brasses, bolts &c. Cast iron pit wheel 12ft. 6in. high put together in halves with good strong bolts. English oak bridgen post with step brass, regulating screw, bolts &c. Cast iron Wallower, 3ft. 6in. diameter, pitched, trimmed & hung upon shaft, with 16 good screws. Cast iron spur wheel with iron teeth, turned, pitched, trimmed & hung with good ham'd iron keys, 6 cast iron stone nuts, geared with wood cogs, bored and hung upon cones, Turned all over, 6 cast iron bridgen posts with round brasses and raising screws. 6 sets of ham'd iron standards to raise the nuts out of work, with 6 sets of lighter screws, stilyard irons &c., one set of regulators with brasses, levers, &c. 4 pairs of French stones 4ft. 2in. diameter, 4 patent stone boxes with brass rings, screws, &c. 4 cast steel damsels, 4 steel springs, 4 cast iron rings, 4 maces, 4 sets of vats, 4 hoppers, 4 shoes, 4 bearers, brasses &c. 4 corn screens, 7 cast iron bridgen posts, 6 cast iron bridgetrees, 6 cast iron plates for stones to bridge upon. Two long iron plates at back of hurst to tie the iron frame together, chipped, filed and fitted together with strong bolts, two ham'd iron upright shafts as shown in the Drawing and four mitre wheels, 2 to drive the flourmill &c. & 2 to sack tackle. Cast iron carriages, plumblocks &c. bolts & brasses, one wheel pinion on cross shaft to drive flour machine with long cross shaft. Cast iron carriage bearings, bolts, &c. Two bevil wheels and nuts at the head of the machine to reverse the machine, new patent flour machine, fitted up complete, new patent flourmill and new sifter. The above work made and fixed in a workmanlike manner will amount to the Sum of Nine Hundred and Fifty pounds, Ten Shillings. |

|

£950.10.0 March 1850. |

I remain. Your Obedt. & Hble. Servt. John S. Buttifant. Millwright |

|

|

Millwright's

plate from 1850-1 rebuild

|

|

The wheel that John Buttifant built and installed was still in situ in 2004 - 154 years later. |

|

There was a

paper-mill at Oxnead several years before 1716; in that year one of the

early paper-makers, William Seaman, died. It is not known whether or not

Seaman was the first occupant, or if this mill pre-dates either of those

already mentioned. An inventory of the goods of Seaman survives in the

Norwich Archdeaconry series, but this had been badly damaged, and that

section reading 'in the mill' has been almost totally destroyed. The only

lines legible being; 'All the paper - - - work

House wad - - - . . .£12 00 00.' and

'All the paper s - - - zing in the loft . . .£9 00 00.'

It appears that the mill passed to Seaman's son because Shorter notes

that in 1717 William Seamen of Oxnead, paper-maker, took an apprentice

named James Dey. |

|

While Joseph

Ames and his son Daniel Ames were running the mill in 1779, Daniel's son

Edward Ames, went on to run Stoke

Holy Cross mill. |

|

|

Workers

outside the mill in 1910

John William Grix (later to become owner) is in the centre |

|

During the

first quarter of the 20th century, the Grix family, who also ran the next

mill upstream at Burgh, converted the flour production

machinery from stone grinding to the more efficient steel roller system.

|

|

The

river lucum missing c.1950 |

|

The

river lucum missing in the 1970s |

In 1940 John

Moseley and Pitt Rivers formed the Agricola Paper Mill Co. It was probably

at this time that the remaining milling machinery was removed. Two large

concrete vats were built on the ground floor and were used for bleaching

pulp. One was built over the area where the pit wheel would have been. A shed with a large chimney was built to the rear of the wheelhouse. This was where the pulp was boiled prior to being processed in the mill. Several Polish men used to work and apparently generally live in this area. John Moseley tended to replace worn wheel paddles with any available material, consequently many of the remaining paddles have sheet metal sections. |

|

|

|

|

Oxnead wheel - 9th January 2003

|

The

wheel with sheet metal paddle sections - 2003

|

|

| When parts of the building were found to be unsafe, repair work was carried out. However, this proved to be insufficient and the mill was finally closed down in the 1950s. |

|

|

May

1962

|

Over the years

the whitened bricks started to revert to their natural colour and during

the 1960s first the pitched roof on the house side gable went followed in

later years by both lucums. A new brick bridge had also been built just downriver of the old lock replacing the wooden structure further below. |

|

|

|

January 1963

|

Tailrace

August 1967

|

|

|

|

Before roof gable renovation - c.1983 |

|

|

|

|

Mill and wheelhouse January 2003

|

9th

January 2003

|

|

Jim & Barbara

Crampton owned the mill from 1957 and used it to store 3 large organs.

One originally came from the Carlton Cinema in Norwich and another from

Norwich Haymarket. The third came from outside the county. At one point,

for a short time, deep litter chickens were kept on one floor of the mill behind a canvas partition. |

In the 1950s the wheel was connected to a generater to produce electricity for the nearby Mill House. |

|

The derelict sheds in the 1970s before the chimney collapse |

|

Seeing Oxnead Mill on the website reminded of two events in my life.

I was born in 1937. Aged 15 I went to Blackpool on a week's holiday with

a friend and his family. John and I couldn't wait to get ourselves over

to Squires Gate airfield. We were to fly for the very first time. We paid

ten bob apiece (50p) and were thrilled to climb aboard an 8-seater twin-engined

De Haviland Rapide for a ten minute flight taking us around Blackpool's

famous tower. All passengers got a nice certificate stating the type of

aircraft and the fact that they had flown at a height of over 500 feet.

Blackpool Tower stands at 518 feet! The certificate was signed by 'Captain

Jim Crampton'. Several years ago, I learned of Oxnead Mill and its collection

of organs. I was surprised to learn the name of the mill's owner and wondered

if it was the same 'Capt. Jim Crampton'. Needless to say, Jim wrote a

very pleasing letter in return and invited me to Oxnead Mill at anytime.

He went on to mention that his business of flying progressed to where

he owned and piloted an airliner in conjuction with a travel business.

|

|

|

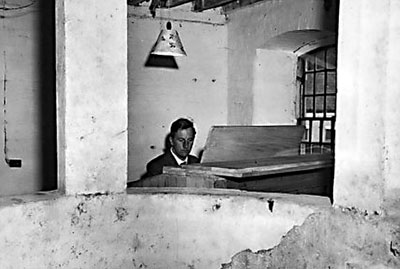

Jim Crampton playing an organ in 1963

|

The picture of an organ recital at Oxnead Water Mill actually shows Mr. J. G. Crampton, owner of the mill. Although Mr. Edwin Gates had been invited to play at the recital, our photographer visited beforehand and was lucky enoiugh to take this shot of Mr. Crampton at the organ. Dick Le Grice wrote in to say that he used to be an organ builder with the now ceased firm of Hill, Norman & Beard, makers of the Christie orgasns. He explained that Jim Crampton not only built the organ in the picture, but also purchased a small Wurlitzer organ and installed it in Oxnead Mill, later on adding a Compton organ (the one from the Haymarket cinema) and later still a Christie. All of these were pipe organs, as no electronics were available in those days. He goes on to say: "Jim Crampton was a flying man and flew from a field in Felthorpe, later taking a hanger on St. Faith's airfield, expanding this into Air Anglia and eventually Norwich Airport. In the early days I used to fly as a passenger with him to Spalding to tune the organ in the Baptist church, driven from the landing ground by his brother Ted." |

|

In 1959 a turbine costing £800 was installed to provide electrical power for both the organs and the rest of the property. In order to provide an unrestricted flow of water to the turbine, the lower paddles of the wheel were removed. The dynamo was housed outside the main structure in order to prevent the mill being classed and rated as a power station. The turbine was bought from Sir Michael Peter of Iford Manor who was related to the builder that constructed Norwich Thorpe railway station. |

By the 1970s the pulp boiling shed was becoming derelict, although for a time it was used to store an aircraft fuselage. One night the chimney collapsed. The shed remains were then removed. |

I was born at Oxnead at Lime Kiln Farm whose meadows led down to the mill and my cousin Susan Crane now lives in the new large house adjacent to the mill! What a co-incidence. Our farmhouse was demolished after we left in about 1960 and replaced by a modern house on the same site. We all remember Jim and Barbara Crampton who also owned the Travel Centre in |

|

|

|

Part of the organ

|

2nd

floor January 2003

|

|

Record sleeve of organ music played at the mill |

|

|

Bypass 27th December 2007 |

Wheelhouse 27th December 2007 |

|

Bypass sluice 27th December 2007 |

|

18th April 2007 |

|

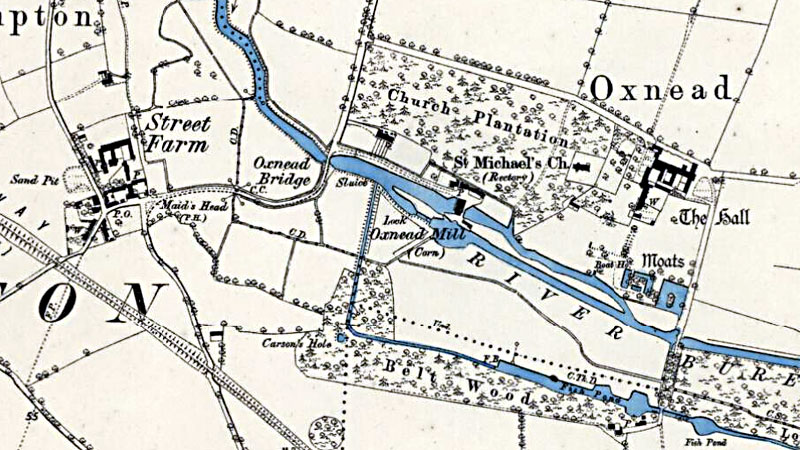

O.S. 6" Map 1885 (not to scale) Courtesy of NLS map images |

|

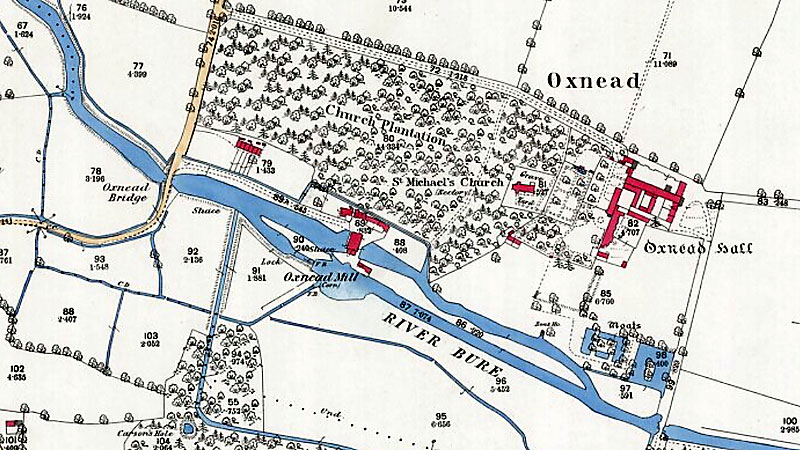

O.S. 25" Map 1885 (not to scale) Courtesy of NLS map images |

|

|

O.S. Map 2005 Image reproduced under licence from Ordnance Survey |

|

1716: First

mention of the mill as a papermill on death of William Seaman - papermaker

Kelly's 1883: William Browne & Son, millers

Kelly's 1904: William Browne & Son - millers (water) & merchants

- Stand 15, Corn Exchange, Norwich. Head Office, The Grange, Marsham |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TG2278 2398 | Copyright © Jonathan Neville 2003 |