|

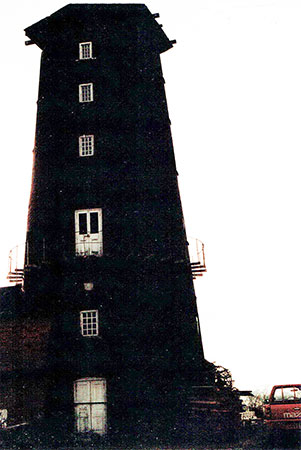

Caston towermill

|

|

|

c.1910

|

|

Caston tower mill was built for Edward Wyer in 1864. The six storey tarred brick tower was 55 feet high to the curb. The 30 inch thick walls were 26 feet outside diameter at the base and 17 feet outside diameter at the curb. The 6 bladed left handed fan and its frame were attached by wire stays to the Norfolk boat shaped cap with its gallery and petticoat. The stage was set around the second floor. The four patent sails each had 8 bays of 3 shutters and 2 bays of 2 shutters, struck by lever and these powered the right handed 4ft underdriven stones, comprising of two pairs of Derby Peak stones and one pair of French burr stones. |

|

William Wright, a builder of Caston constructed the mill and millwright Robert Hambling of Dereham, whose name appeared on several of the castings, installed the machinery. Jacob Canham was employed as the bricklayer and was paid 2d. per hour. William Wright 's young son John also worked on the project. |

|

Edward Wyer's father John Wyer, had previously been miller and baker at Caston, running the postmill that was later demolished by Edward to make way for the towermill built on the same site. |

|

A two storey brick Granary was built on to the southeast side of the mill. A first section was probably built at the same time as the mill with a further section being added to the southwest at a later date. Etched into the bricks on the outside of the south wall: |

JAS A |

||

189. |

||

G. GREEN |

GILBERT |

|

FW |

||

1897 |

||

1930 |

GILBERT |

|

1930 |

|

On the internal ground floor wall of the mill and the east wall of the granary were the initials RW |

| A datestone above a first floor window inside the mill bears the inscription EW 1864. |

RW |

AW |

RKM |

||

FN |

HF |

AW |

HF |

INC |

B |

RRM |

|||

NRM |

36 |

|

and in pencil: |

Besides the name of Robert Hambling on original castings, the names of other ironfounders give a rough date of alterations and various pencilled notes on the woodwork the date of other items of interest. On the two remaining bridge trees, the name, W. H. WIGG & CO. EAST DEREHAM on one shows it to have been a replacement of about 1880. This firm also cast the iron part of the remaining horse. On the other bridge tree C. RIX. DEREHAM indicates its casting between 1892 and 1904, though its fitting here was later, as it came from Saham Toney towermill. The French burr runnerstone has four cast iron balance box covers with, Edward Banham. Gorge Green Tared this Mill March 5th 1900 |

|

John (Jack) Thomas Wyer was the son of Edward Wyer and Frederick Wyer was Jack's brother. |

|

James Anderson, son of Golding Anderson was born c.1880 and died 23rd December 1962 at the age of 82. He was buried in Grimston churchyard. |

|

The initials RRM and NRM listed above on the Bin Floor, referred to employees of Martins of Beccles who carried out work at the mill in 1936. Edward Banham was the father of Charles Banham and Nelson Banham. Nelson was born on 10th May 1877 and died on 8th March 1949. He apparently had the habit of carrying on a conversation with himself in a normal voice as he walked. |

|

George Green died on 1st October 1967. |

|

The mill had five floors above the ground floor: |

... brake wheels ... The smallest is at Caston, which is 6ft. 9ins. in diameter and built on top of another wheel. |

Drive from fan spindle to rack on curb. Worm drive with rack at the side outside. |

|

|

1932 |

12th September 1934 |

THE HURRICANE OF SUNDAY |

While the storm was at its highest the fears and consternation of the inhabitants were greatly intensified by the alarm of fire being raised and the ringing of the fire bell. People ran about almost panic stricken. It was found upon enquiry that a message had just been received from Caston stating that Mr Wyre's flour mill was on fire. Dereham & Fakenham Times - 30th March 1895 |

Edward Wyer remained running the mill, baking and farming business until he died on 5th July 1897 aged 76. The business was then put up for auction although Edward Wyer's name was misprinted in the advertisement. |

|

|

Mill working - 6th April 1938 |

1958 |

CASTON |

On Thursday October 7 ALEXANDER BANHAM is favoured with instructions from the Executors of the late Mr. James Wyre to Sell by Auction at the Duke's Head, the Tower WINDMILL, DWELLING HOUSE, FARM PREMISES and about 12 Acres of excellent Arable LAND. Particulars of Messrs. Grigson & Robinson, Solicitors, Watton and the Auctioneer. Lynn Advertiser - 17th September 1897 |

The mill was not sold at auction in 1897 and Edward Wyer's second eldest son James, took the business over. Edward's youngest child was Catherine Maud Wyer and she eventually married Benjamin Knott, who in turn took over the business in 1910 when James Wyer retired. Benjamin Knott ran the mill until 1940, although he was in partnership with his son Edward, for the last few years. In 1940 the mill and farm business were bought by James Bilham. |

James Wyer eventually became bankrupt and later paid 20/- in the pound. |

Benjamin and Ted Knott acquired a Ruston Hornsby oil engine, which was used to power a pair of stones on the upper floor. The mill had long ceased to mill flour and was grinding for animal feed during the 1930s. James Bilham discontinued grinding in the mill and removed the centre pair of Derby Peak stones that had come from Saham_Toney, along with the right hand pair. However, Ted Knott persuaded him to retain the pair of French burr stones. |

|

|

c.1970 |

1st September 1970 |

Edward Charles Knott was born on 12th January 1911 and died on 26th June 2003 at the age of 92. Mr. Knott, Ted or Teddy was born in Mill House, Caston in 1911, the only child of Benjamin and Catherine Knott and grandson of Edward Wyer who built Caston towermill in 1864. On leaving school, he worked at the mill with his father. He used to deliver animal meal, going round with a horse and cart and when storms came in the winter he recalled the "noise of the sails" and that he used to have to go out and lock them. When the mill was working, every two hours, he had to go to the top to oil the brass bearings around the windshaft. Maybe this explains why he had trouble with his knees later in life! |

Ted Knott, who was also the church organist for well over 25 years, lived in a bungalow at Northacre in Caston. He lived opposite the clay-lump cottage Everleigh that was the home of the Wyer family during their latter years in the village. Ted Knott was the last of the Knott family from Caston. |

Fred Wyer had a large family but none of his sons had sons of their own so the family name ended. |

| Edward Wyer started business in Caston as a baker, his premises being probably the house which until recently was occupied by Mr. and Mrs. Thacker immediately west of Willow Farm, Northacre. (The baker's oven there was removed by Mr. John Bullen and the space made into a room). At some stage he farmed Home Farm and probably lived in the farmhouse. In 1864 he had the mill built and at about the same time the smaller part of the Mill House was built. At first he employed a miller who lived in this house but later Edward Wyer himself moved to Mill House at which time he enlarged it. The day's work began by greasing the cogs on the head wheel and wallower. Normally the cap would be facing into the wind but if during the night the wind had dropped to nothing and there was by morning only a slight breeze from a different direction, insufficient to activate the fly and rotate the cap, I would have to climb out on the fly staging and turn the cap into the wind manually by using the worm and pinion mechanism. It might be necessary to give the fly a start by hand. Once a fortnight the flywheel (which was called simply the fly) would have to be greased. While at rest the vanes (which is what e called the shuttering) would be open, thus allowing the wind to blow straight through the sails. Before releasing the brake the vanes would have to be closed so as to present the maximum sail surface to the wind, especially to a light wind. To do this we would hang a number of weights on the chain from the shuttering rod. On windy days the vanes would be partially opened by the wind and sometimes in very high winds they would go with the vanes open. Mind you, one never dare let her work with the brake on because the friction would have caused a fire. Once the mill had started I would help in any possible way but the main jobs were moving corn and meal to and from waggons and lifting heavy sacks of corn by pulley up to the dust floor from which the corn would be fed into the bins below. The meal had to be shovelled into sacks and wheeled to the granary for storage. Sometimes we would buy corn, mill it and sell it later and at other times we ground corn belonging to farmers. About every two hours I would go to the top of the mill to oil the brass bearings around the upper end of the windshaft, because they tended to run hot. I had also to make sure that there was always a free flow of grain from the hoppers to the stones. Sometimes part of an ear of corn would produce a blockage. There was always book-keeping to be done. Elsewhere my Uncle John would often be dressing a pair of stones, that is, re-cutting the grooves on the grinding surfaces. he needed my help to lift and turn the running stone with the aid of pulleys, and while he spent about two days in dressing a pair of stones I would help in sharpening the steel bills used for dressing. A pair of stones would last about a week. If there was a change of grain different stones would be used. For example you would not use the same stones for wheat as for barley. Wheat stones were of French burr while barley stones were Derbyshire peak stones. You needed a good wind to use wheat stones. A wheel adjustment could be made to change the distance between stones and thus alter the fineness of grinding. In stormy weather the wind might change too quickly for the fly to turn the cap and sails. One had then to be on guard against the mill becoming "tail-winded" with the wind directly behind the sails instead of in front of them. Then she would run backwards until stopped and altered and the vanes would fly shut of their own accord. (Remember that the curved surface of the sails was always presented to the wind). If the corn was on the damp side it would tend to "paste up" the stones. In this case we would add a little maize to clear the grooves. Of course, it would not do to store grain which was too damp and which tended to "heat up". I can just remember milling for flour in in the days before the 1914-1918 war, but since then and until we ceased milling in about 1940 we were producing animal foods because there was so much imported flour. Besides wheat and barley there was maize ground for ducks (Caston was well known for Mr. James Bilham's flocks of ducks) and beans which were mixed with barley meal. we would grind all the year round, all through the night sometimes when there was a good wind and plenty of grinding to be done. In the end it was the uncertainty of the wind as against the reliability of the internal combustion engine which put the windmill out of business. We had installed an oil-driven mill in the granary so as to keep working on windless days. From time to time there was maintenance work carried out by millwrights and in particular replacement of the two sails. On of these suddenly snapped off one day while I was working in the mill. Apart from the loss of the sail (and loss of the mill until repairs were carry out) there was no other damage. Minor maintenance work including replacing broken apple-wood cogs on the head wheel. Ted Knott - as quoted in A History of Caston Norfolk - John S. Barnes, 1974 |

Norfolk millwright John Lawn bought the mill in October 1969 from James Bilham's widow, with the intention of restoring it. However, although he was involved with the restoration of other mills in conjunction with the Norfolk Windmills Trust, he never succeeded in restoring his own mill. A link to John Lawn's obituary and the memorial plaque dedicated to him at Old Buckenham towermill can be found on the Links page. |

When John Lawn bought the mill the sails had lost their shutters, the fantail had mostly disintegrated and the tower had not been retarred since 1936. However, the mill machinery was still in working order. |

By 1975 the adjoining granary had been converted to residential use and the mill was housing the business of Lennard & Lawn (Millwrights) Ltd., the last firm of millwrights in Norfolk. The sails were intact but without shutters, the fantail had been dismantled but the single pair of French burr stones stones remained. |

On 17th August 1977, Lennard & Lawn removed the cap frame from Gt Bircham towermill and brought it back to Caston mill. On 6th December 1977, Lennard & Lawn removed the cap frame and windshaft from Dereham towermill and brought the windshaft back to Caston mill. |

Caston mill was featured in the December 1970 edition of Norfolk Fair. |

|

|

10th September 1978 |

1984 |

|

c.1980 |

|

1982 |

Besides the name of Robert Hambling on original castings, the names of other ironfounders give a rough date of alterations and various pencilled notes on the woodwork the date of other items of interest. On the two remaining bridge trees, the name, W. H. WIGG & CO. EAST DEREHAM on one shows it to have been a replacement of about 1880. This firm also cast the iron part of the remaining horse. On the other bridge tree C. RIX. DEREHAM indicates its casting between 1892 and 1904, though its fitting here was later, as it came from Saham Toney towermill. The French burr runnerstone has four cast iron balance box covers with, Edward Banham. Gorge Green Tared this Mill March 5th 1900 |

Mrs. M. E. Hepple of Old Coulsdon in Surrey wrote a letter to Philip Unwin to say she was the granddaughter of Frederick Wyer, who was a journeyman miller. He had a shed in the field to the north of the mill that contained an engine he used for grinding corn. A bungalow was later built on the site of the shed. |

|

|

Stones and tun on the 2nd floor c.1982 |

Main shaft and wallower on the 5th floor c.1982 |

|

Windshaft bearing c.1982 |

On 23rd November 1983 the cap and sails were removed for replacement and a temporary roof was fitted. Timber for two new sheers had been delivered by 14th February 1984. |

|

1989 |

|

Eastern Daily Press advert for Savills - 2nd July 2010 |

My great aunt Mabel Chapman lived in the mill house, this would be around the early 50s. Her two sons who live with her Clifford and Stanley Chapman worked for Jim Bilham as he was known. |

I am a Great-Great-Granddughter of Edward Wyer, my maternal Grandmother, Mabel Holyoak neé Wyer was a daughter of Frederick Wyer. |

Came across your site while researching Bracondale_Mill, my mind shot

back to my birth place and early child hood. Caston. I remember the

Mill quite vividly. A Mrs Chapman and her sons Clifford and Stanley

lived in the mill house. The two sons worked the mill, whether they

owned or rented I could not say. My father was blacksmith in the

village forge, while my mother worked at whatever she could find in

between bring up 6 children. One of her jobs was cleaning house for Mrs

Chapman for a few years. I would go with my mum to the mill with her,

being allowed to go and find Clifford or Stanley and watch with them the

mill working, one of my favourite things was Clifford tie a rope round

me, wedge open the floor hatch and drop me down to the bottom. |

I descend right down the tree from the brother of Thomas Wyer born 1764 Carbrooke (several generations back from John and Edward the millers). |

|

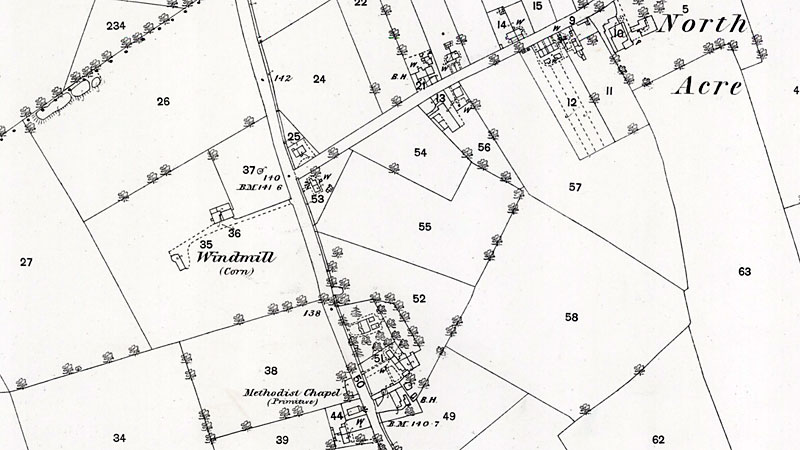

O.S. Map 1888 Courtesy of NLS map images |

Unallocated Caston miller: |

1864: Tower mill built by William Wright for Edward Wyer

Kelly's 1879: Edward Wyer, miller & farmer

White's 1883: Edward Wyer, miller & farmer |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TL95109816 |

Copyright © Jonathan Neville 2005 |