|

Hickling

towermill |

|

|

c.1885

|

Hickling towermill was built in 1818 and had an 8 storey tarred tower that was substantially constructed with brickwork of 30 inches thickness at the base. The tower was 60 feet to the curb and 71 feet to the cap ridge. The mill stood back from the road, alone in a field. Unusually, for aesthetic reasons, the windows were all built one above the other and in order not to detract from the overall strength of the tower, 13 of the 28 windows between the 1st and 7th floors were false. A bake office was being operated on the premises by the 1860s. |

The mill had a Norfolk boat shaped cap with an 8 bladed fan and a gallery. The four double shuttered sails each had 9 bays were controlled by a 9 ft. diameter brake wheel and drove 3 pairs of French burr stones, 2 flour mills, a cylinder and a jumper. The wallower was made of wood with cast iron teeth set in segments and 3 dressing machines and an oat crusher were driven from a set of very flat bevel cogs mortised into the original wooden rim. A stage had been set around the 4th floor by around 1900. |

Grinding capacity: |

|

| 1818: | 12 to 14 lasts per week = 240 to 280 sacks (coombs) i.e. 80 to 93 coombs per week per pair of stones (3 pairs) |

| 1819: | 10 to 12 lasts per week = 200 to 240 sacks (coombs) i.e. 66 to 80 coombs per week per pair of stones (3 pairs) |

Tower approximately 61 ft. to the edge of the petticoat |

To be Let With Immediate Possession |

To be Sold by Auction Sometime in May or June next |

To be Sold by Auction By Mr. Kemble At the White Horse, Hickling |

To Millers To be Sold or Let |

To be Let With Possession at Michaelmas next |

|

4th September 1938 |

Miscellaneous |

To Millers |

To Bakers |

To Journeymen Millers |

Situations Vacant |

Situations Vacant |

Situations Vacant |

Situations Vacant |

|

19th May 1980 |

Mill & small Farm |

Mill & small Farm |

HICKLING, Norfolk |

|

|

1989 |

1991 |

The large tower was substantially constructed with brickwork of 30 inches thickness at the base. It had no reefing stage, which must have proved rather inconvenient in a changeable wind. The clasp-arm brake wheel had diagonal braces between the spokes and drove a solid wooden wallower with two sets of cast iron teeth, one of which powered a wooden sack hoist bollard. The wooden upright shaft and a dog clutch at bin floor level joined both sections. Two of the original three pairs of stones remained in their original cases - although these were in poor repair and incomplete. Stone nuts and spindles have disappeared, as had most of the tentering gear. The underdrift stones had at some time been repositioned, the clasp-arm spur wheel being extended with the addition of a double rim with iron teeth, cast in two pieces. The shanks of the original wooden cogs remained in the original rim of the spur wheel, below which a set of bevelled cogs drove a layshaft for auxiliary machinery that included three flour dressers and an oat crusher. |

|

11th May 2008 |

Pencilled inscriptions on the 3rd floor: |

Pencilled inscriptions on the 6th floor, mostly on corn chutes: |

Relating to the photograph at the top of the page: This is my Grandfather Thomas Whittleton and my father Walter Garrett Whittleton taken about 1885.

The Mill was owned by my Gt. grandfather Israel Royal Garrett, somewhere on a beam is a record of the date IRG took his son-in-law Thomas into partnership.

Edna Miller - 17th April 2006 |

|

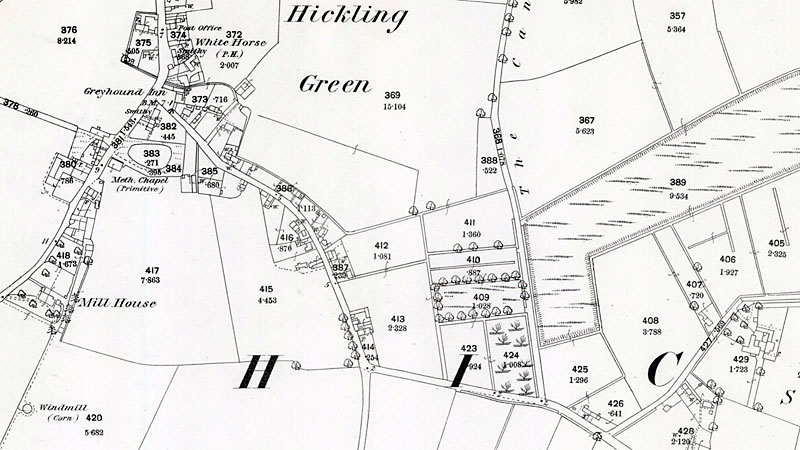

O.S. Map 1884 Hickling towermill bottom left Courtesy of NLS map images |

c.1818: Mill built

c.1885:

Thomas Whittleton, miller |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TG40862300 |

Copyright © Jonathan Neville 2005 |