|

|

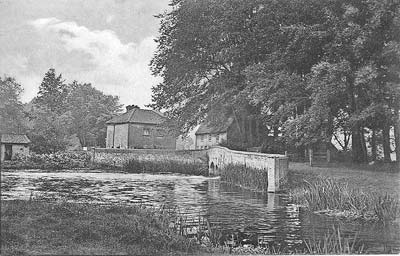

c.1910

|

|

Lyng Mill

River Wensum |

|

|

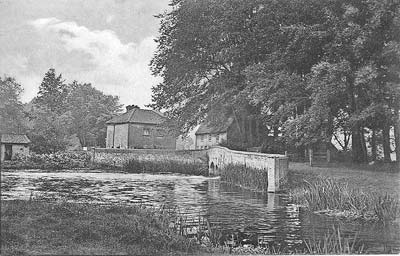

c.1910

|

|

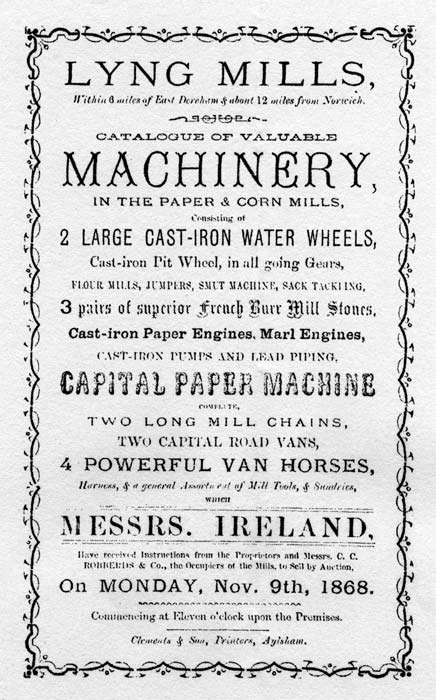

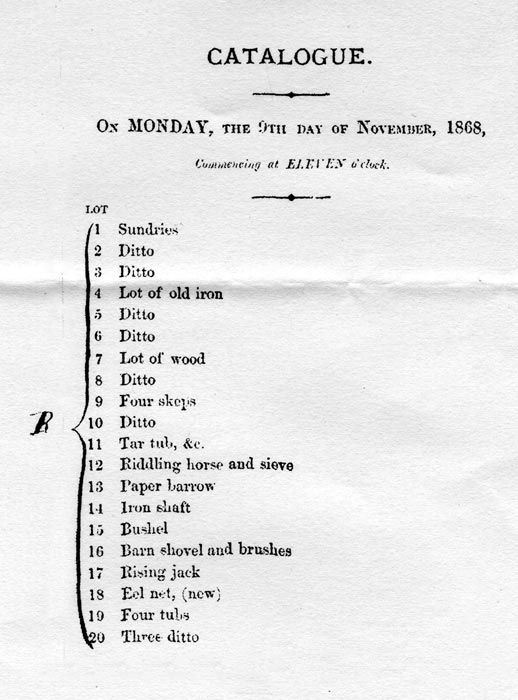

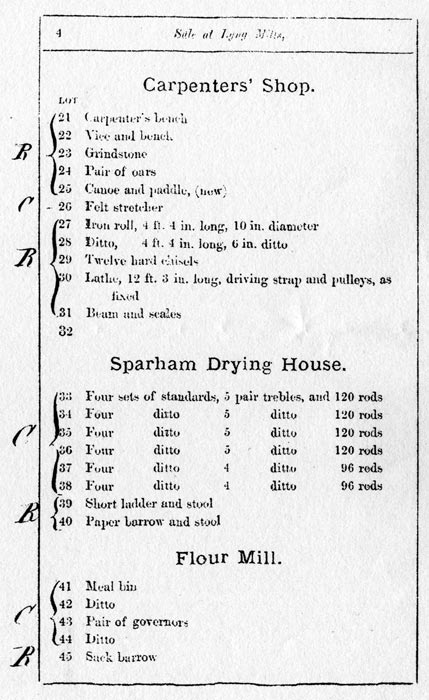

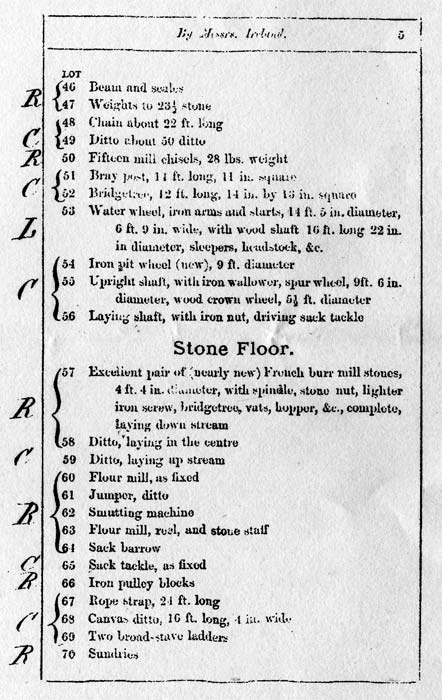

Lyng mill was built as a flour mill in the early 1400s but over the centuries it was operated as both a flour mill and a paper mill. When the mill was rebuilt after being badly damaged during the riots of 1832, it was configured to run as both a flour mill and a paper mill using two cast iron wheels. |

As operated prior to closure c.1868: |

|

|

1st

May 1977

|

|

Back in the time of Henry IV (1399-1413) a "New Cut" was made to alter the river's course in order to accommodate the mill. Unfortunately, this resulted in law suits over the fishing rights. |

|

|

Mill

house and mill bridge September 1967

|

|

Lyng mill was

mainly known as a paper mill although it also ground corn.

|

|

It is said

that blotting paper was discovered at Lyng mill by accident. |

We breakfasted, supped & slept again at home -

Mr Du Quesne called on me this morning about 12. o'clock and about 12. I

took a ride with him to Ling and there we dined & spent the afternoon

at Mr Baldwins with him & his Wife & youngest Daughter and Mr Priest

of Reepham - Mrs Baldwin seems to be rather of a gloomy Complexion - with

a Beard - Before Dinner we went into Mr Baldwins Boat & went up the

River a little way to take up some Hooks that were laid for Jacks, but never

a Fish - Having done that Mr Du Quesne, Mr Priest & self went and saw

the Paper Mills close to Mr Baldwins - Mr Du Quesne & myself bought

a Ream of writing Paper 20 Quires belonging to the same I had one half and

he the other 10 Quires apiece - I paid for mine - 0: 5: 0 The Master Mr

Amerton went with us and shewed us the whole Machinery which is indeed very

curious We had for Dinner at Mr Baldwins some fricasseed Rabit ............ Parson Woodforde's diary - 12th February 1778 |

|

|

September

1967

|

|

There was a poor Man on Wednesday or Thursday last killed at Mr Hammertons

Paper Mill. The Lever of the Press by some means got loose & knocked

his Brains out.... |

|

Dies Solis I breakfasted, dined, supped & slept

again at home - Another dreadful Misfortune happened to Mr Hammerton

at Lyng this morning about 4 o’clock the Paper Mill on fire and Burnt

with such Rapidity that it burnt down the whole Mill and very near burnt

down the dwelling House but that escaped - I sent Will down in the Evening

after News And he brought me word that the Damage sustained was between

3 and 4000 Pound - The Mill was insured for 2000 Pound however - There

was 1000 Pound worth of Paper burnt - No Body can tell how it came on

fire at present - I am exceeding sorry indeed for the Event. |

|

|

You will be sorry to hear that a few weeks ago a fire broke out in

Mr Hamerton's Mill, which intirely consumed it with the contiguous offices

& all the stock in them; the house, tho' three times on fire, was

saved; the loss is not yet estimated, but must amount to some thousands;

he bears it

with wonderfull fortitude, but I fear that he is much hurt. The son is

at sea with a squadron, midshipman to a 50 gun ship.

|

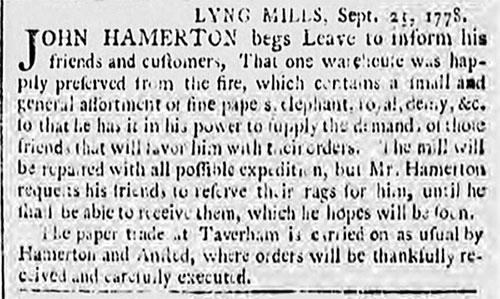

Lyng and Taverham Paper Mills |

The Partnership of HAMERTON and ANSTED expired on the tenth Day of October last, they therefore take this Opportunity of resuming their joint Thanks to their Friends for the Favours conferred on them, and beg Leave to inform them, that the Trade of the above Mills will in future be carried on for their separate Accounts by John HAMERTON, at Lyng, and John ANSTED and Son, at Taverham, where the Favours of their Friends will be very thankfully received. -- Any Person who has any Demand on the said Partnership Account are desired to send in their Bills, that they may be discharged. They have by them a regular Assortment of every Kind of Paper (that is to say) Writing and Printing Imperial, Writing and Printing Royal, Writing and Printing Medium, Writing and Printing Demy, Writing and Printing Post, Writing and Printing Copy, Writing and Printing Fools-cap, Writing and Printing Pot, Crowns of every Sort, and every Sort of Packing Paper for the Manufactory, particularly of Atlas, large and small; Elephant, large and small; Royal, large and small; Demy, large and small; Brown and Hand Elephant, Brown and Hand Royal, Shop Paper, Bonnet Paper that will fence Water, and every Article whatsoever in the Paper Trade. The best Price is also continued for fine Rags, and every kind of Paper Stuff. N.B. To be Lett, and entered upon immediately, or at Lady-day next, a handsome well built House, Brick and Tile, situated in Lyng aforesaid, with Garden and Orchard, well-planted with all Sorts of Fruit Trees; also a four-stalled Stable and six Acres of rich Pasture Land thereunto belonging, and Right of Commonage on two very extensive Commons. Lyng is a small pleasant village and in a very good Neighbourhood, five Miles from East Dereham; four from Reepham, and eleven from the City of Norwich. The said House is very convenient for a small Gentleman's Family, or for a Gentleman who is fond of sporting, being an exceeding good Country for Game of all Kinds. - A Pack of Hounds are kept within two Miles of the Said House. -- For Rent and further Particulars enquire of John HAMERTON, at Lyng Paper Mills. Norfolk Chronicle - 1st February 1783 |

|

|

31st

December 2002

|

|

History of Lyng Mill |

Shorter notes

that John Hamerton the paper-maker at Lyng took an apprentice named John

Carter in 1764. Hamerton is known also at Taverham

from 1758, and he was in partnership with John Anstead there, and at Lyng,

from around 1770. By 1778 Lyng mill was described as 'a paper mill in which

is carried a considerable manufacture and in which a great number of hands

are employed throughout the year'. In the same year Parson Woodforde visited

the mill and bought one half of a quire of writing paper for five shillings.

He was shown the machinery by Hamerton and thought it 'indeed very curious'.

Unfortunately within eight months the mill had been burnt to the ground, the Norwich Mercury of 3rd October reported that a fire on the previous Sunday, had within a few hours destroyed the mills, the adjoining offices and all the stock contained in them. Throughout the eighteenth century paper-mills were particularly prone to fire, largely due to the combustible nature of the rotting rags. By 1781 the mills were nearly rebuilt and in 1783 the partnership between Hamerton and Anstead expired and the former once again took over the sole control of the business at Lyng. An advertisement in the Norfolk Chronicle for 1st February 1783 lists the whole range of types and sizes of paper available from the mills. John Hamerton died in 1800 and his successor, Thomas Hamerton, was declared bankrupt only four years later; the mill then passed to John Abbot Dusautoy from Romsey, Hampshire. Dusautoy is of particular interest because soon after moving to Lyng he published a book. The paper-maker's ready reckoner; or, calculations to shew the prime cost of any ream of paper was printed at Romsey in 1805 'for, and sold by the author at Lyng paper-mills. . .' This work was not produced for the general public but compiled from the experience of the author to assist other paper-makers 'to save time and prevent others selling at random, often at or even under Prime cost to their own evident injury and that of the trade in general'. The author's experience did not come cheaply for he charged five guineas for a small octavo pamphlet of thirty four pages, a price which would seem excessively high even today. However the copy of this work in the Colman & Rye Libraries in Norwich bears witness to the undoubted usefulness of the publication, for in places it is covered with an owner's calculations, and has also been well thumbed. (This copy is signed by the author and may perhaps have been used by him?). From the tables it is apparent what considerations needed to be taken into account when pricing different grades of paper. One of the most important elements in the calculation of the price of finished paper was the wastage, the difference between the weight of rags and the weight of paper that was produced. Rags were bought by weight and priced according to their quality, the finished paper being sold according to the weight per ream. It was therefore essential to take into account the wastage when calculating the cost of rags that had been used to make a given weight of paper. This could vary between one pound in four and one pound in eight depending on the quality of the rag used. Rag which wasted at one-in-four was valued between ll/2d and 51/4d per pound, one-in-six at between 31/4d and 7d, one-in-seven and one-in-eight at between 5l/4d and 9d. One ream of finished paper might weigh anything between five pounds and twenty three pounds depending on its quality. Dusautoy lists also the following expenses for the paper-maker but does not specify how much each contributed, giving only one table for their determination. These are rent, taxes, insurance, repairs, wages, interest, fuel, candles, stable expenses, travelling, utensils (moulds, felts, planes, boards and levers) bad debts, oil, lard, soap, flannel, packing paper, various kinds of stationery and finally the duty. The last table is one to calculate the wages of the journeymen paper-makers on either a fixed weekly wage or by piece work. This tables assumes a six day week and that the wages would vary from between twelve and thirty shillings for that work. On piece-work payment would vary between ll/4d and 3d for each 'post' of paper produced (that is for a pile of sheets of paper, interleaved with felts, ready for pressing and drying, the number of sheets varying with the size of the paper). The range of payment would be caused by the fact that there were three different jobs involved; the vatman who made the sheet, the coucher who removed it from the mould, and the layer who pressed and drained the water. The vatman would be paid more than his colleagues as his job required considerably more skill. The table also shows that a team of men working on piece-work would have to produce twenty posts each day to earn as much as men on a fixed rate (taking the average figures from each scale). Possibly this was therefore the quantity of work produced by a team of men at Lyng in one day? (It would have taken the average journeyman five weeks before he had earned the five guineas which Mr. Dusautoy asked for his book.) It is not clear how long Dusautoy remained at Lyng, it is possible that he was in partnership with James Rump (later of Swanton_Morley mill) as the watermark 'Dusautoy and Rump 1807' is fairly common. The mill is next noticed in 1829 when Robert Hudson the paper-maker appeared before the Court of Exchequer in Norwich on 28th October; he was found guilty of producing paper at Lyng not bearing an Excise mark and therefore attempting to avoid duty. In 1832 the mill was destroyed during machine-breaking riots, but was later rebuilt and owned by the firm of Robberds and Money until the mid 1860s. David Stoker |

The extensive paper warehouses at the mill were burnt down with a large stock, in 1778. From this mill the river enlarges itself and flows to Lenwade bridge. |

|

In 1797, a letter was sent from Mr. Nathaniel Kent, a lawyer in Lincoln's Inn, London, to Sir John Lombe. In the letter he wrote: I have Mr. Anson's authority to offer you the whole of his estate of Lyng for £14,000 including the timber. It consists of a very fine manor and such rents etc. as nearly as I can calculate them, to £72.5.11d. The Manor Farm is let to Rising at £66. The other farm, part of which was once yours, let to Powell at £111/ the piece of lane let to Clarke at £5. The mill let on lease of which about 20 years are unexpired £63 |

|

Wheelrace April 1969 |

|

Norwich, Nov. 30 - Several men were apprehended yesterday, and lodged in Wymondham gaol. On Saturday, a mob of several hundreds, armed with hammers, saws,

&c., attacked the paper-mills at Tronham, and completely destroyed

the machinery, which was of nearly the valise of 2,000l. They proceeded

from that place to Lyng paper-mill, and committed damage to the amount

of 700l. Similar acts of violence have been committed in other parts of

the neighbourhood, and the loss of the damage in machinery alone, within

the last few days, is estimated at almost 5000l. As soon as the alarming

proceedings were made known in Norwich, a large body of the military proceeded

to the spot, and apprehended ten of the party concerned in the outrage

at Farnham, who have been since lately lodged in the county prison. |

|

|

Document dated 30 Sept 1835 - version omitting repetition and legalese Notice from E S Clarke (agent to Edward Lombe James Stoughton and Jn Mitchell) to Mr William Johnson, Mr John Rising Staff, Mr Samuel Lovick and all persons concerned I do hereby give you notice that by an Indenture of Lease dated the 31st day of August 1815 made between: 1. Sir John Lombe baronet 2. John Abbott Dusantoy whereby a messuage with certain Water Mills situate at Ling and Sparham and the water wheels water works engines machinery and other things belonging were leased [demised] to John Abbott Dusantoy for the term of 23 years. And it was agreed that all the machinery implements and effects that JAD should use during the term for the manufacturing of Paper within the mills should be of full value of £200 over and above the the value of the water wheels and water works and Sir John Lombe during the said lease and at the expiry thereof have a lieu upon the machinery etc used by JAD for the sum of £200 and also JAD should leave and yield up to Sir John at the end of the lease all the machinery etc that he has used for manufacturing paper within twelve months And I do further give you notice that the messuage water mills land and premises are now legally vested in Edward Lombe esq of Great Melton as Tenant for life and the Revd James Stoughton and John Mitchell esq as trustees under will of Sir John Lombe. And further that you are not to sell convert remove part with or dispose of the Water Mills Water works machinery implements now being in the leased premises (you do so at your peril) And I give notice that a Bill in Equity is proposed and will be immediately filed by Edward Lombe and his trustees and that an injunction will be applied for to restrain you and all other parties from proceeding to sale. ------------------- Sir John Lombe (baronet and High Sheriff of Norfolk) died in May 1817 aged 80. So the Edward here is his heir (he was Edward Beevor but had to take Lombe surname to inherit the Great Melton estate). It looks as though, by 1835, the lease or at least the mills had fallen into possession of some men called Johnson, Staff and Lovick who were planning to sell it. The agent for EL and his trustees are filing a legal suit to prevent them doing so. It appears that John Rising Staff was a Norwich solicitor later Town Clerk. Sam Lovick appears as auctioneer in Norwich (1830 directory) but may have died the year before. There is also a Lovick & Johnson Woollen Drapers. |

Thomas Skipper was on Monday last brought before Saml. Bignold, Esq. on the charge of stealing a brass cock or syphon, weighing 160 lbs. the property of Messrs. Robberds and Day, paper manufacturers, at Taverham in this county, in whose employ the prisoner has lately been at Lyng. He was apprehended in London, by Sergeant Peck, A., of the Norwich Police force, and was by Mr. Bignold remanded for further examination.

Norfolk Chronicle - Saturday 29th June 1839 |

Thomas Skipper, aged 28, was convicted of having, in the month of Oct. last, stolen from a cottage at Taverham, one metal cock and plug, the property of Henry Robberds and Star??ing Day. - The prisoner was found guilty and was sentenced to 7 years' transportation.

Norfolk Chronicle - Saturday 6th July 1839 |

|

Gentm |

Thomas (my g-g-g-grandfather) was captured following an advertisement in the Police Gazette on 1st April 1839 and sent to the Prison Hulk York at Gosport where he served four of his seven years.

Clare Daley - 20th January 2008 |

|

|

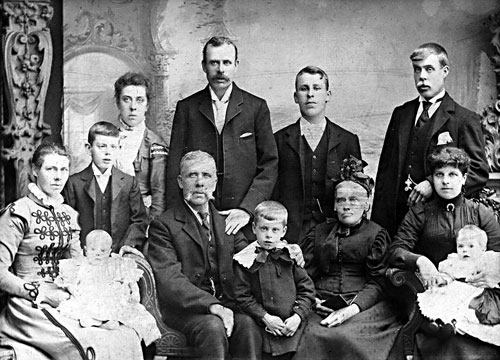

Thomas Cann & family - c.1890 |

Thomas Cann worked at the mill in the 1860s. He was born c.1841 in Elsing and married Louisa Hewett from Foxley b.1833. Their son John was born in Lyng on 27th October 1867 but died on 4th November 1869, aged 2. Thomas had a second son, Frederick, who was born in 1870. Not long after the mill closed in 1868, the Cann family moved to the North East England, although it appears that they later returned to Norfolk. |

|

|

|

|

|

|

|

|

|

|

Mills |

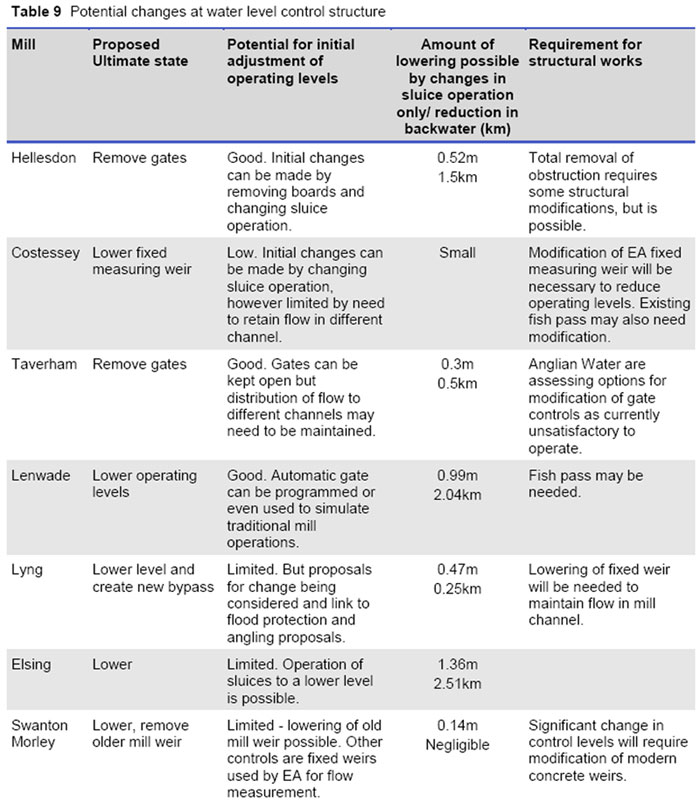

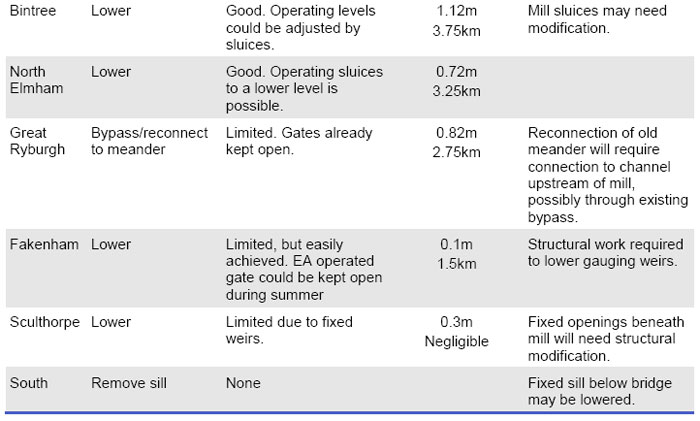

|

6.16 The mill structures have a profound influence on the river system in the Wensum catchment. If high retained water levels continue upstream of the mills, they would form a significant constraint on the effectiveness of river restoration. Physical modifications at mill sites should aim to restore a more natural longitudinal profile to the river and to remove or reduce physical barriers to the movement of fish and wildlife. Whilst historically a number of mills have been in existence for centuries these have always very actively stored and released water and the cessation of working of the mills in combination with dredging has had a significant impact. 6.17 The recommended actions at mill structures are shown in Table 9. At a number of sites there is no mill building and removal of water level control structures would be the desired course of action. However, often there are multiple channels at a mill site and it is likely that some hydraulic controls would be needed to maintain a split of flows to all channels. These would probably take the form of a fixed crest and a natural chute that would allow the passage of fish and woody debris. At locations where the water level control structures are part of the historic mill building, there is often a variety of passageways and the best way to lower levels will need to be identified using more detailed survey. Initial action can be taken at low cost by merely adjusting operating levels using the available gates and stop boards. The reduction in head that could be achieved at a typical dry weather flow is also summarised in Table 9. The estimated maximum reduction in backwater length through changing the operational level of the sluices (that is, without the need for major engineering works) is 18km. This would reduce the length of the River Wensum SSSI affected by backwater from mills from 67% to 40%. To achieve this it would be necessary to ensure that no channels downstream of gates or fixed weirs are affected, but this could be a cost effective start to the Wensum restoration. 6.18 It is likely that at some locations, where the channel course has been altered and the mill channel is significantly higher than the natural channel, the main flow could be diverted upstream of the current mill location. Maintaining some flow to the original mill weir is likely to be preferable for aesthetic and heritage reasons, so by-passing is likely to be required in conjunction with lowering of the mill weir. Sites where such a solution is envisaged are at Great Ryburgh and Lyng. 6.19 The control structures at Costessey, Swanton Morley and Fakenham are used for flow gauging by the Environment Agency. Lowering these weirs may mean that the existing gauging arrangements will need to be replaced by other methods, such as ultrasonic techniques. The weir on the main channel at Swanton Morley has a two stage drop and a significant reduction in water level could be achieved there without affecting flow gauging through the bridge. 6.20 A former mill known as Gogg's_Mill near to Fakenham was removed as part of the drainage improvement works of the 1950s. The channel upstream of the mill has narrowed significantly through the accretion of silt berms, and provides a good case study of the extent to which natural recovery can help restore natural river form and function. 6.21 As part of the River Wensum Water Level Management Plan being prepared by Entec (2007) the views of some private owners on changes in operating level have been canvassed. In broad terms this is not opposed, but there is concern to maintain an attractive setting incorporating some mill pond in line with the historical context particularly at: 1) Elsing 2) Great Ryburgh 3) Bintree 4) North Elmham 5) Lenwade 6.22 A reduction in the retained water level at mills may constrain the ability to direct water through all the existing channels at mill sites, should this still be required, there may be a need to carry out physical modifications to some of the subsidiary water level control structures. River Wensum Restoration Strategy - Natural England, 26th June 2009 |

My GGGrandfather was Thomas Cann born 1841 Elsing. His son John born 27th October 1867 Lyng is the baptism record you refer to on your site I believe he died in Lyng 4th November 1869. I'm descended from his brother Frederick born c1870. What I do find interesting is when the Mill ceased Working in 1868. My family shortly after moved to North East England to work there and maybe it was because of this Mills closure that they did move. Also some of the names mentioned such as Skipper I have as a Middle name in my tree and the name Hudson also married into my extended Cann Family at 1 point. |

My husband's great great grandfather was a Robert Hudson born in 1809 in Lyng so I am beginning to wonder if he was the Hudson who appeared in court for avoiding duty in 1829! It was his son, Robert David Hudson, who moved to the London area and it was his daughter who was my husband's maternal grandmother - sadly she died when may husband's mother was only 4. I think the first Robert's father was a John. Anyway both Hudsons and Clarkes obviously have connections with the mill. |

I have a marriage in Lyng in 1813, Benjamin Squires and Sophia Wells, the point being is that he had traveled from Herefordshire where he was a paper maker, clearly he sought work in Lyng in 1813 give or take. He later moved all over England to some beautiful places ending back in Leominster. |

Zachariah Wells who was killed in the machinery in 1845 was my Great Great Grandfather and his wife was Mary Wells. |

Zachariah was Louisas brother. Louisa's illegitimate daughter Thirza married Samuel Skipper. William Wright snr and junior are both in the 61 census as paper workers. I haven't worked out where Matthew and Thomas Skipper fit in yet but they're family I'm sure. |

|

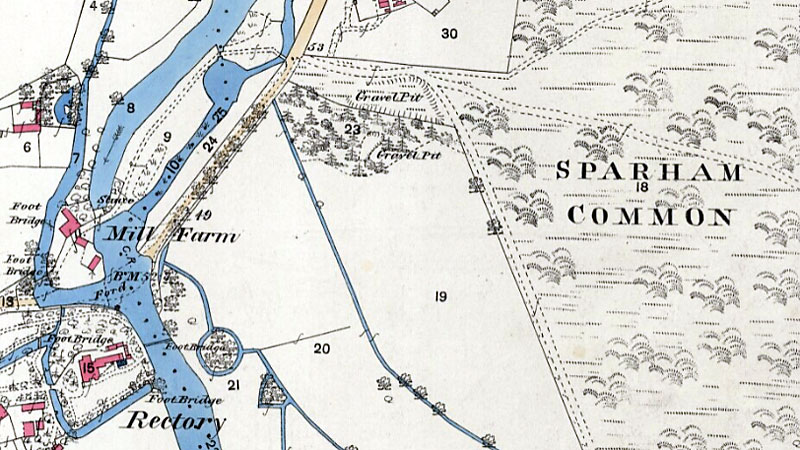

O. S. Map 1882 |

The above map clearly shows the dotted line of the parish boundary tracing the original path of the river that ran to the east of where the mill was, rejoining the main river flow to the south of the mill. The new river course was dug to accommodate the mill and the mill dam.

|

|

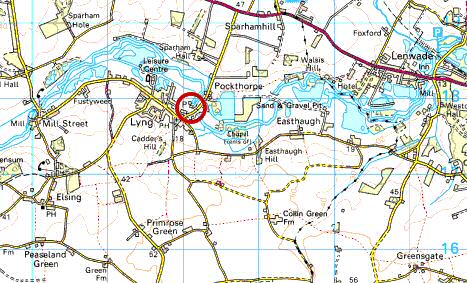

O.S. Map 2005 Image reproduced under licence from Ordnance Survey |

White's 1836: John Brown, Millwright |

|

1764: John

Hamerton took on apprentice John Carter

Death certificate of 9th May 1845: Zachariah Wells died in the machinery of the paper mill Parish Baptism Record 5th January 1851: Robert Howard, papermaker

Parish Baptism Record 22nd August 1852: Robert Howard, papermaker Parish Baptism Record 4th September 1853: Richard Parnell, papermaker

Parish Baptism Record 2nd December 1860: William Sewter, papermaker

Parish Baptism Record 27th July 1862: William Wright, papermaker Parish Baptism Record 9th October 1864: William Wright, papermaker

Parish Baptism Record 14th October 1866: William Wright, papermaker |

If you have any memories, anecdotes or photos please let us know and we may be able to use them to update the site. By all means telephone 07836 675369 or

|

| Nat Grid Ref TG 07141786 | Copyright © Jonathan Neville 2003 |